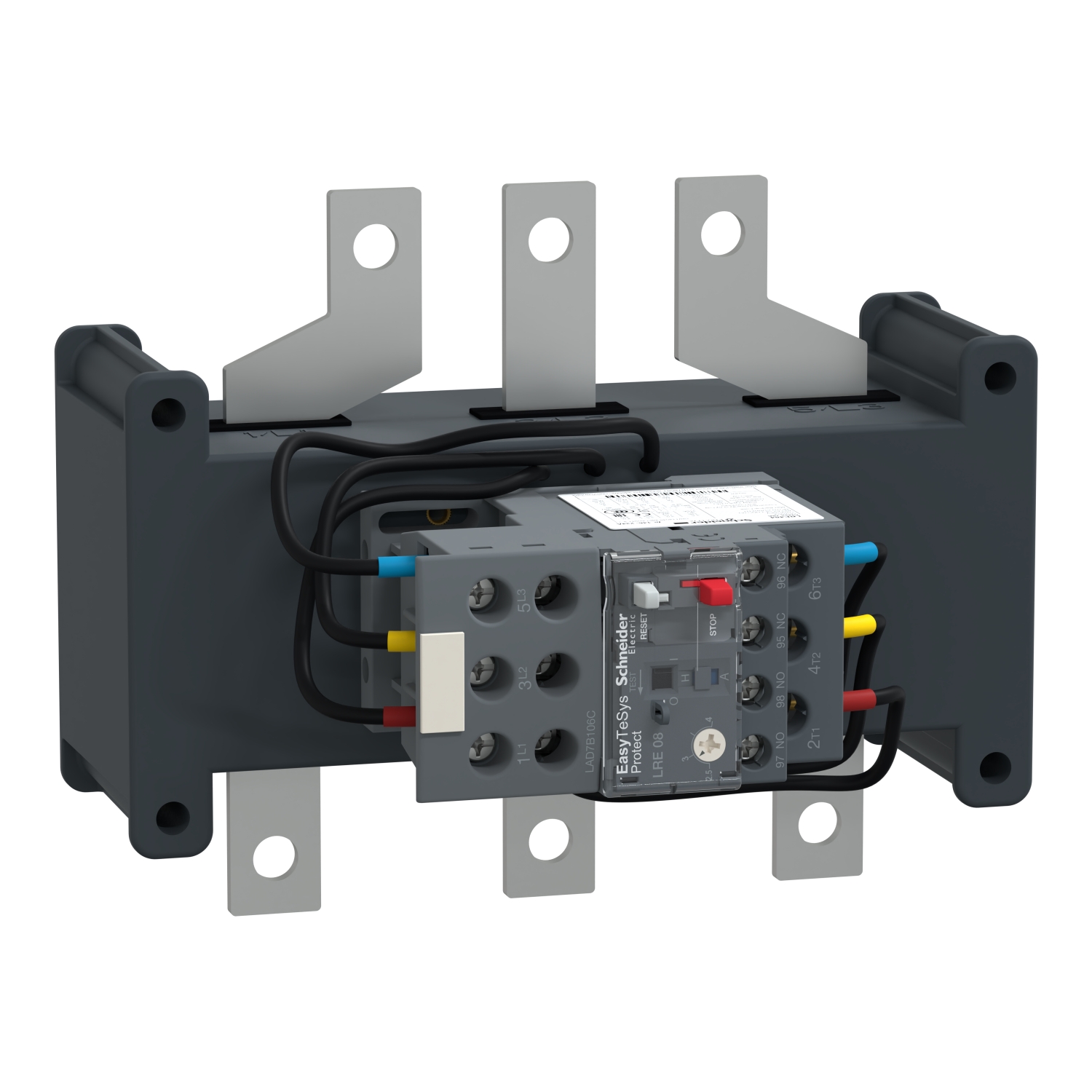

Schneider LR9F5369 | TeSys LRF – electronic thermal overload relay – 90…150 A – class 10

| brands | Schneider Electric |

|---|

Add a review

You must be logged in to post a review.

Schneider LR9F5369 | TeSys LRF – electronic thermal overload relay – 90…150 A – class 10

Technical Specifications

-

Brand: Schneider Electric

-

Series: TeSys LRF

-

Model: LR9F5369

-

Type: Electronic Thermal Overload Relay

-

Adjustable Current Range: 90 to 150 A

-

Tripping Class: 10 (Fast Motor Protection)

-

Phase Imbalance and Loss Detection: Yes

-

Reset Mode: Manual and Automatic Reset

-

Mounting Type: Direct mounting on TeSys F contactors

-

Connection Type: Screw terminals

-

Operating Temperature: -20°C to +60°C

-

Compliance Standards: IEC 60947-4-1

Key Features

-

Precise Overload Protection: Uses electronic sensing for more accurate motor protection compared to conventional thermal relays.

-

Adjustable Current Settings: Allows fine-tuning between 90 A and 150 A for optimized motor safety.

-

Quick Tripping (Class 10): Ensures fast response to overload conditions, reducing motor damage risk.

-

Auto/Manual Reset Options: Provides flexibility in reset operations for uninterrupted performance.

-

Direct Mounting on TeSys F Contactors: Simplifies installation and saves panel space.

-

Phase Failure Protection: Trips the circuit in case of phase loss, preventing motor burnout.

-

Robust Design: Built for harsh industrial environments, ensuring long-term reliability.

Applications

-

Heavy-Duty Industrial Motor Protection: Ideal for large three-phase motors in manufacturing plants.

-

Pumps and Compressors: Ensures safe and efficient operation by preventing overload and overheating.

-

HVAC Systems: Protects large-scale ventilation, cooling, and air-handling systems.

-

Material Handling Equipment: Used in conveyors, cranes, and automated production lines.

-

Mining and Oil Industries: Provides critical motor protection in demanding environments.

Reviews

There are no reviews yet.